Published in the August 2025 issue of Decarbonisation Technology, a new technical article titled “Anatomy of the Alkaline Electrolyser: Optimisation Strategies for Green Hydrogen Production” explores the increasingly complex challenges of real-time gas analysis in industrial hydrogen generation systems.

As the energy sector pivots towards low-carbon and renewable solutions, hydrogen has emerged as a cornerstone of the global decarbonisation strategy. Among the various green hydrogen production pathways, alkaline electrolysis remains one of the most commercially mature and widely deployed technologies. It is cost-effective, scalable, and well-suited for integration with renewable energy sources such as solar, wind, and hydropower.

However, while the underlying chemistry of alkaline electrolysis is well established, the demands placed on process monitoring and control systems are evolving rapidly—especially in large-scale applications where system integrity, energy efficiency, and product purity are paramount. In their recently published article, Gregory Yakhnin, Galina Gurina, and Gregory Shahnovsky provide a thorough examination of the operational and analytical challenges associated with measuring hydrogen (H₂) and oxygen (O₂) concentrations within such systems.

The Importance of Gas Monitoring in Alkaline Electrolysis

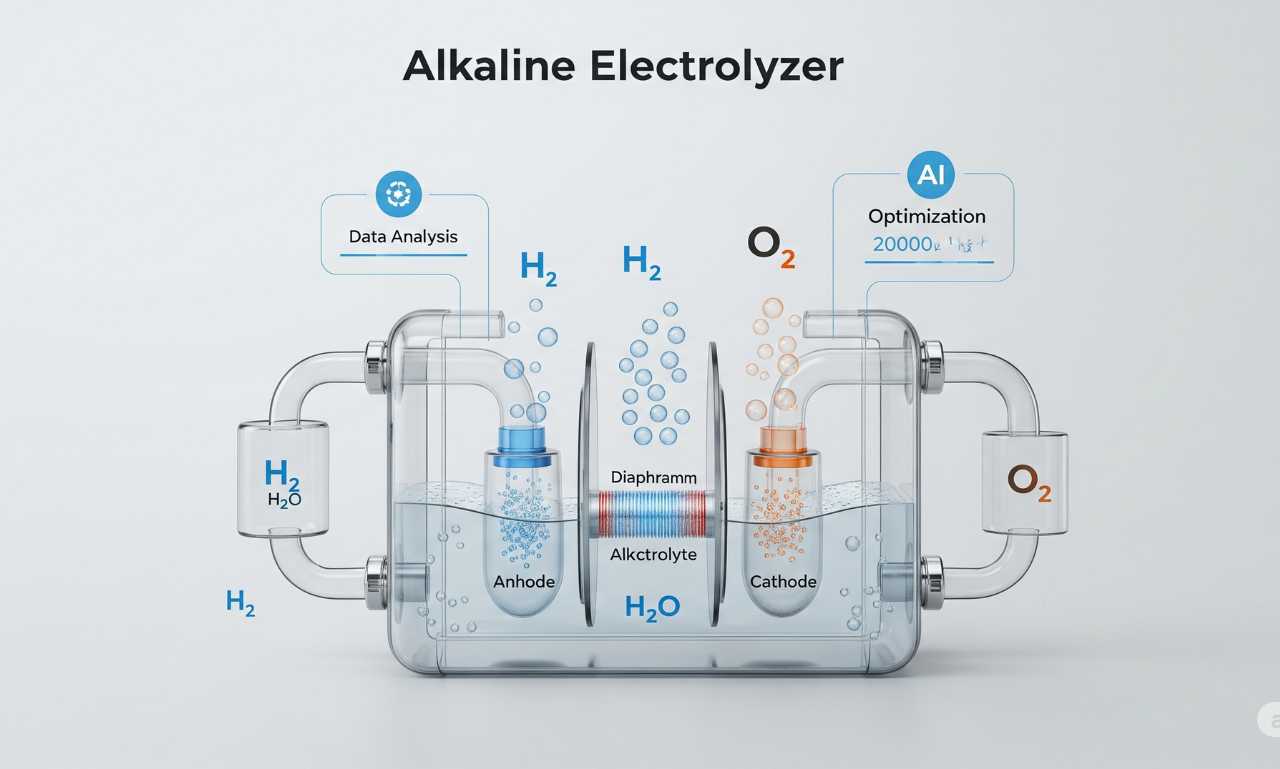

The production of green hydrogen via electrolysis involves the splitting of water into hydrogen and oxygen using an external electrical current. In alkaline electrolysers (AELs), this is achieved by passing the current through a potassium hydroxide (KOH) solution, with hydrogen being generated at the cathode and oxygen at the anode.

Maintaining the correct gas composition at each point in the system is essential not only for process efficiency but also for operational safety. Excess oxygen in the hydrogen stream—or vice versa—can pose significant explosion risks, particularly when concentrations approach the flammability threshold. This makes continuous, accurate, and responsive gas oxygen and hydrogen analysis a non-negotiable requirement in industrial settings.

Operating Conditions and Measurement Complexity

What sets AELs apart from laboratory systems is the highly variable and often harsh environment in which they operate. The article outlines several key parameters that can affect gas measurement accuracy:

- Pressure fluctuations: Operating pressure can range from 0.8 to 40 bara, requiring sensors and analyzers to maintain calibration and stability across a wide spectrum of conditions.

- Temperature variability: Internal temperatures can fluctuate between 40°C and 90°C, influencing sensor performance and potential condensation within sampling systems.

- Relative humidity: Humidity levels range from 20% to 100%, contributing to moisture carryover and potential interference in optical or electrochemical measurements.

- Flow dynamics: Gas velocities may span 0.5 to 10 m/s, introducing turbulence, laminar-to-transitional flow shifts, and dynamic sampling inconsistencies.

- Electrolyte contamination: KOH carryover—ranging from 0 to 1,000 ppm—can corrode sampling lines and damage sensors, especially in extractive systems.

These factors create a non-trivial measurement environment where conventional gas analyzers, especially those designed for static or clean applications, may deliver unreliable results.

Key Monitoring Challenges in Practice

The authors identify several persistent challenges in AEL monitoring:

1. Cross-Sensitivity and Signal Drift

In systems where multiple gases are present, analyzers may exhibit cross-sensitivity—responding not only to the target gas but also to others present in the stream. This is particularly problematic in environments where hydrogen purity must exceed 99.9%, and even trace oxygen content is consequential.

Additionally, long-term exposure to temperature and humidity cycles can lead to sensor drift, which degrades accuracy over time and necessitates frequent recalibration—adding cost and operational burden.

2. Sample Extraction Limitations

Many legacy systems still rely on extractive sampling techniques, where gas is withdrawn from the process, conditioned (i.e., filtered, dehumidified, and pressure-regulated), and then analyzed. While this method is familiar and well-understood, it introduces:

- Lag time, reducing responsiveness to rapid changes

- Safety risks, particularly when dealing with flammable gas mixtures under pressure

- System complexity, including tubing, valves, pumps, and conditioning units

- Potential for contamination or leakage, especially in humid or corrosive environments

3. System Integration and Communication Gaps

In complex industrial environments, measurement data must be seamlessly transmitted to supervisory systems (e.g., SCADA, DCS, or cloud-based platforms) for visualisation, alerting, and control. Traditional gas analyzers may not natively support modern communication protocols, creating integration bottlenecks and reducing the value of acquired data.

A New Approach: Fusion Method with AI-Enabled Optimization

To address these challenges, the authors introduce a novel monitoring concept based on a hybrid model they refer to as the Fusion Method. This approach combines multiple sensor technologies with AI-based optimization and inference algorithms, allowing for adaptive responses to fluctuating conditions in real time.

Key elements of the method include:

- Real-time compensation for temperature, pressure, and humidity influences

- Predictive modeling to detect sensor drift or anomalies

- Multi-point correlation between gas concentration and operating context

- Onboard analytics for rapid validation and pre-processed output signals

- Open communication interfaces (e.g., Modbus, OPC UA) for seamless system integration

By shifting from a reactive to a data-driven proactive monitoring framework, the Fusion Method enables smarter decision-making and fewer maintenance interventions, while enhancing safety margins through early detection of deviations.

Implications for Total Cost of Ownership (TCO)

From an economic perspective, upgrading monitoring infrastructure using such methodologies can yield significant savings. The authors argue that while AI-enabled or in-situ gas analyzers may entail higher initial investment, they often reduce operational expenditure in the following areas:

- Reduced recalibration and technician visits

- Longer sensor lifespan due to better environmental compensation

- Minimized product loss or downtime due to faster detection of faults

- Improved compliance and reporting accuracy

These savings, when extrapolated across multi-megawatt electrolyser installations, can contribute to substantial reductions in Levelized Cost of Hydrogen (LCOH), aligning well with national and international decarbonisation targets.

Industry Relevance and Broader Impact

The article arrives at a pivotal moment in the development of green hydrogen infrastructure. As countries pursue net-zero goals, electrolyser fleets are scaling rapidly—from single-stack demonstration projects to full-scale hydrogen hubs. In such deployments, robust instrumentation becomes not just a technical requirement but a strategic enabler of reliable, safe, and efficient operations.

Moreover, the monitoring strategies explored in this article have cross-cutting applications beyond hydrogen production. Similar conditions are found in battery manufacturing, fuel cell development, CO₂ capture systems, and other areas where gas composition and environmental stability are critical.

Where to Read the Full Article

The complete version of “Anatomy of the Alkaline Electrolyser: Optimisation Strategies for Green Hydrogen Production” can be accessed through the following links:

- 🔗 Online article: https://decarbonisationtechnology.com/article/342/anatomy-of-the-alkaline-electrolyser-optimisation

- 📘 Full digital magazine (Page 72): https://ptqmagazines.digitalrefining.com/Decarbonisation-Technology-August-2025/72/

It is featured in the August 2025 issue of Decarbonisation Technology, a technical publication focused on innovative solutions in industrial decarbonisation.

As the writer and founder of this blog, I share insights on Tech, Business, Media, Games, Apps, Gadgets, Cybersecurity, Web Development, Podcasts, and Cryptocurrency. My mission is to educate and inspire with engaging, SEO-friendly content that keeps you ahead in the digital landscape.